SMART NEW TECHNOMET-CONTROL VESA-MOUNT ENCLOSURES FOR HMI/CONTROL ELECTRONICS

FIT TECHNOMET-CONTROL TO MACHINES, WALLS, WORKSTATIONS AND POLES

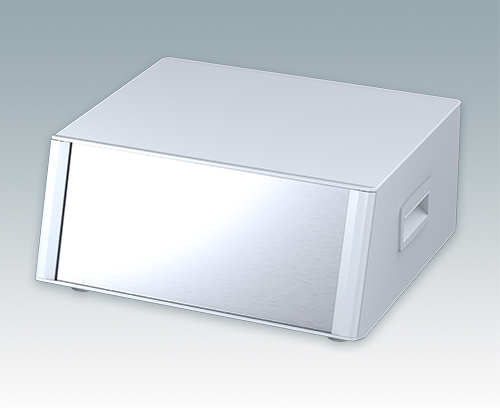

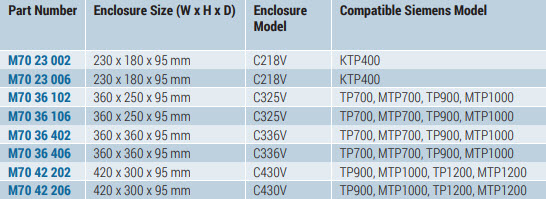

Smart new TECHNOMET-CONTROL is much more than just a new model – it represents a whole new type of enclosure for METCASE. These elegant and versatile housings for standard displays, panel PCs and HMIs are the first METCASE enclosures to be created principally for VESA-mount electronics.

By integrating VESA MIS-D 100 x 100 mm into the design, these advanced enclosures offer a very economical solution for mounting HMI /control electronics on machines or in other locations. Off-the-shelf VESA supports can be mounted directly to the rear of the enclosure. TECHNOMET-CONTROL can also be directly fitted to walls/machines and poles using accessory mounting kits.

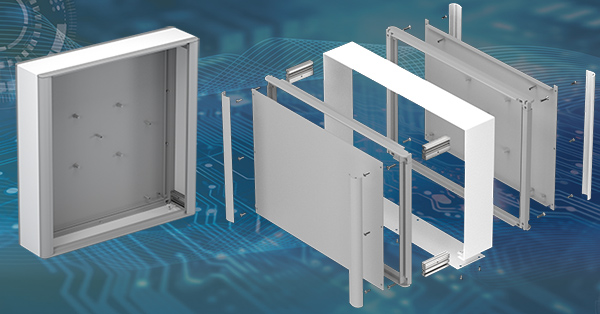

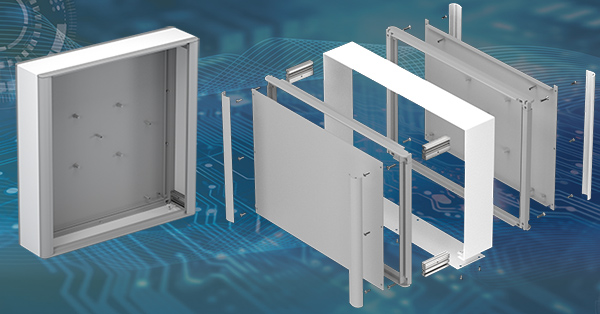

The real secret behind TECHNOMET-CONTROL is the simple but clever design that enables these attractive enclosures to be manufactured more cost effectively than their high-end appearance suggests.

They can be manufactured in bespoke sizes very easily – making customisation viable for volumes as low as 10 or 20 units. It’s all thanks to the construction of the front and rear bezels and the use of four simple extrusions inside each housing.

WHY WE CREATED TECHNOMET-CONTROL

Demand for advanced HMI technology has been increasing, much of it driven by Industry 4.0. Standard displays and panel PCs need to be housed and protected but many of the existing HMI enclosures on the market are large, sealed units for challenging industrial locations.

Here at METCASE, we identified a gap in the market for robust, modern display enclosures for light industrial applications. These aluminium housings need to be tough and aesthetically pleasing – but not necessarily sealed and IP rated.

TECHNOMET-CONTROL is a contemporary VESA-mount enclosure that is manufactured to a visibly high standard – but it can be offered at an intriguing and compelling price-point, thanks to the efficiencies created by its innovative and practical design.

MODERN, COHESIVE DESIGN WITH FLUSH-FIT BEZELS

First impressions matter – which is why TECHNOMET-CONTROL looks significantly smarter and better manufactured than other wall-, arm- and pole-mount enclosures of its size. It has a modern, cohesive design with diecast bezels that fit flush with the main case.

Snap-on trims in the front and rear bezels conceal all the assembly screws, giving a clean and unfussy appearance – and framing the front panel, which is recessed to protect a touch screen and other controls.

TECHNOMET-CONTROL is engineered to finer tolerances than other similar metal enclosures. This is a trait that TECHNOMET-CONTROL shares with the TECHNOMET and TECHNOMET 19” models that preceded it.

And the fact that TECHNOMET-CONTROL shares a common design language with these two other models offers further aesthetic benefits. It ensures that your wall- and pole-mounted products will match your desktop, portable and 19” rack electronics.

TECHNOMET-CONTROL FOR FITTING TOUCH SCREENS

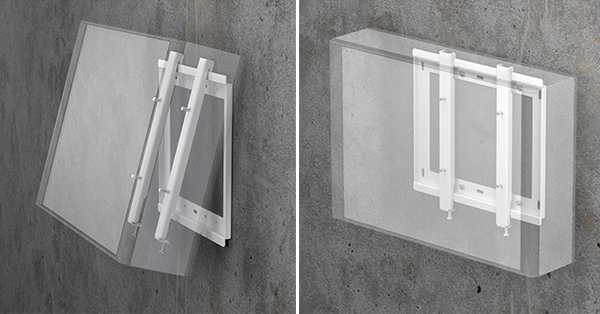

We designed TECHNOMET-CONTROL for mounting touch screens and displays, specifically to accommodate and protect Siemens TP units (sizes KTP400 to TP1200). It can also house screens by other leading manufacturers, including Beckhoff, B&R and others.

The enclosures can be supplied in custom sizes to accommodate your specific touch screens and control equipment. Our sales team will be happy to assist you with the integration of your displays, touch screens and controls.

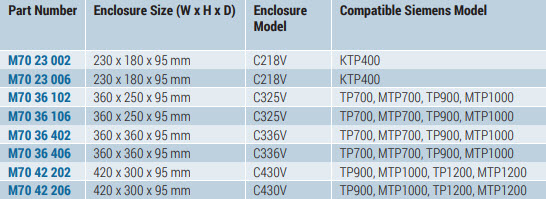

TECHNOMET-CONTROL – SIEMENS TP DISPLAYS COMPATIBILITY

We can supply the TECHNOMET-CONTROL front panels pre-punched with the required apertures for the Siemens displays as shown above, or displays from any other manufacturer you specify. Where necessary we can adjust the external dimensions of the enclosure to suit your specified displays, touch screens, controls and electronics assemblies.

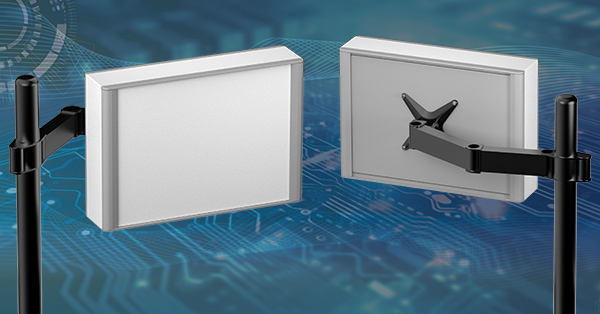

STANDARD VESA MOUNTING

All TECHNOMET-CONTROL enclosures are supplied with a VESA MIS-D 100 x 100 mm mounting point in the rear panel for fitting standard VESA suspension arms, wall brackets and workstation supports. This is a highly economical solution for mounting the equipment on machines, walls and in many other locations, such as a point-of-sale terminal. The VESA M4 fixing inserts are closed at the bottom to stop the VESA fixing screws entering the inside of the housing. The VESA mounting holes are also employed when fitting other mounting accessories (pole mount and wall mounting kit).

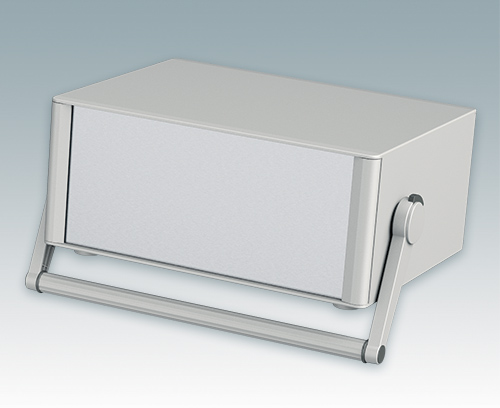

POLE MOUNTING BRACKET

This mounting bracket is designed for easily fitting the housing to a pole or mast – ideal for factory automation applications where the equipment can be located next to a machine or production line. The bracket assembles to the VESA mounting holes on the enclosure rear panel and is designed for fixing to a pole/mast ⌀50 mm or larger (mounting straps are not included in the kit).

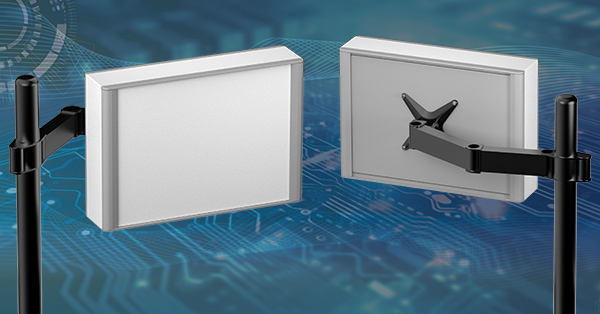

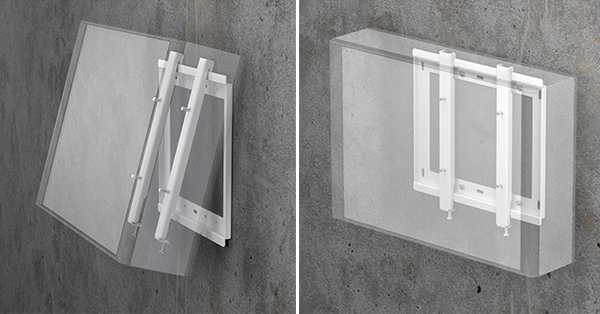

WALL MOUNTING KIT

The wall mounting kits are designed for fitting the TECHNOMET-CONTROL directly to a wall, machine or bulkhead. They are ideal for applications such as building services electronics where the equipment is wall mounted with no visible fixing screws. Two kits are offered to suit the different case sizes. Each consists of three parts: a wall plate and two case brackets. The wall plate includes multiple fixing holes for level location on any surface. The case brackets locate on the wall plate and include locking screws hidden on the underside of the enclosures.

WHICH TECHNOMET-CONTROL ENCLOSURE FOR MY ELECTRONICS?

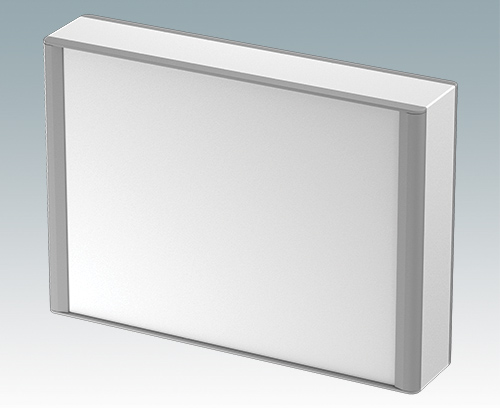

We’ve made TECHNOMET-CONTROL available in four plan sizes at launch: 230 x 180 mm, 360 x 250 mm, 360 x 360 mm and 420 x 300 mm. All four sizes are 95 mm deep, giving the enclosures a slimline appearance – and yet still offering plenty of space for components.

There are two standard colour options – either traffic grey A (RAL 7042), or a combination of traffic white (RAL 9016) and traffic grey A. Both look good but the latter is particularly fetching, being predominantly white with grey front and rear bezels.

We anticipate plenty of demand for these standard colours, if our other off-the-shelf enclosures are anything to go by, but custom colours are readily available too. We have a large selection of colours in stock.

Easy mounting of the electronics has been included in the design right from the start. M3 fixing pillars are provided on the inside of the rear panel for fitting PCBs, electronics assemblies or the accessory mounting plate kit. Also, guide rails and M3 holes in the assembly extrusions are provided for fitting customer-specific internal plates. This offers you a wide choice of options for mounting your electronics.

And every case panel has an M4 threaded earth stud as standard, saving you the job of specifying it as a custom feature. These studs also help to retain the front panel when it’s open for installation or servicing; this is particularly useful if the equipment is mounted at height. Meanwhile, the base panel on the underside offers plenty of space for cable entry. This panel is removable for easy inspection and maintenance.

TECHNOMET-CONTROL Technical Video

View TECHNOMET-CONTROL range >>

SPECIFY CUSTOMISED TECHNOMET-CONTROL ENCLOSURES

Non-standard colours are merely one way of customising your new enclosures. METCASE offers plenty of other options too. And all work is carried out in-house to ensure quality and accountability, and to save you time and money. Services include:

- Custom sizes – all METCASE enclosures are available in custom sizes to some degree. TECHNOMET-CONTROL is one of eight models than can be specified in custom sizes in all three dimensions: height, width and depth/length.

- Custom front panels – manufactured from aluminium or steel, pre-punched with apertures, drilled and tapped, fully finished with powder coating, wet painting, anodising or linishing, and printed or engraved.

- CNC machining – punching, forming, milling drilling, tapping and countersinking.

- Fixings and inserts – a wide choice of threaded inserts and studs. Options include self-clinch nuts, studs, blind standoffs, through standoffs, PCB clip-on standoffs, 90° panel nuts, and cable tie mounts.

- Photo-quality digital printing of legends, logos and graphics up to 1,800 x 1,800 dpi with print areas up to 600 x 420 mm (A2).

View the full range of customisation services >>

GET EXPERT ADVICE ON VESA-MOUNT ENCLOSURES

Need more information about new TECHNOMET-CONTROL or any of our other enclosures? Contact METCASE for expert technical advice on specifying the best standard, customised or fully bespoke enclosures for your next project.

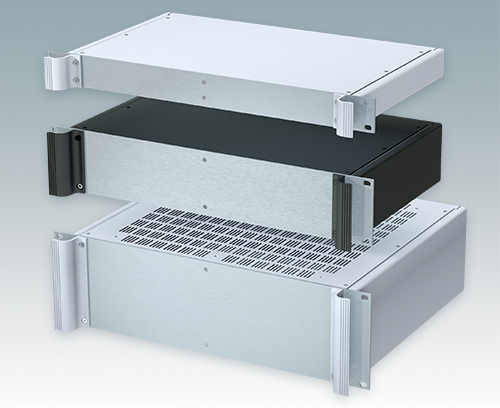

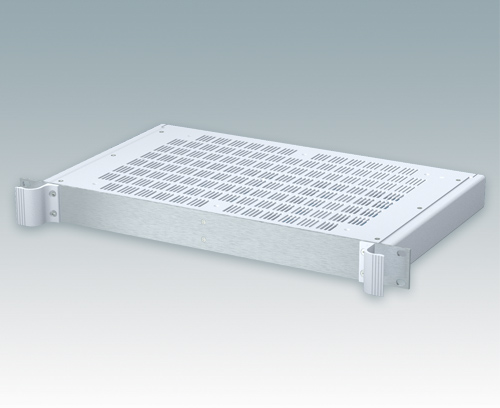

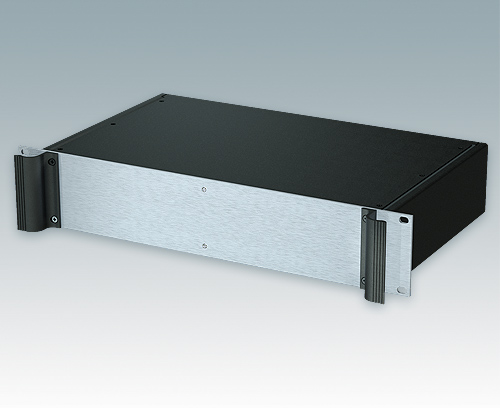

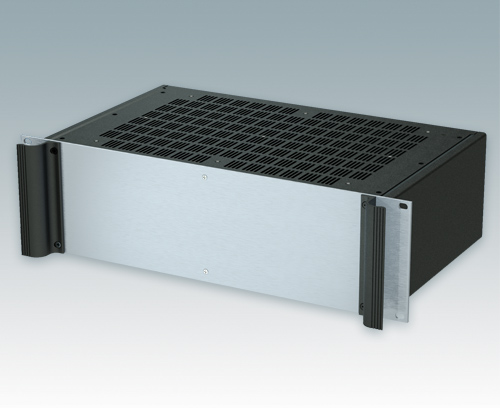

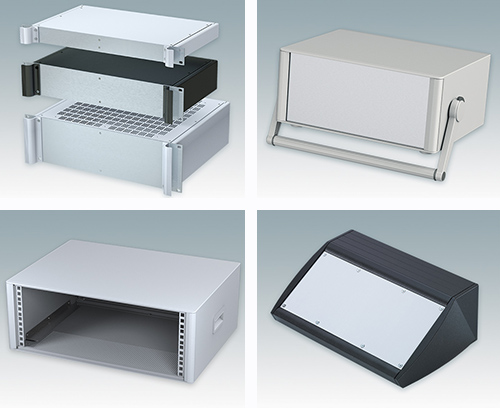

19" Enclosures

19" Enclosures

Metal Enclosures Modern metal enclosures for OEM electronics equipment

Metal Enclosures Modern metal enclosures for OEM electronics equipment

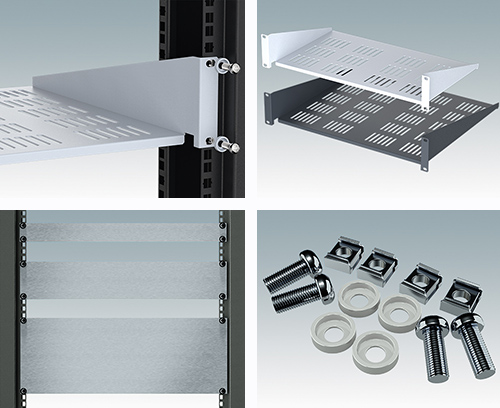

Accessories for Enclosures Extensive range of universal accessories

Accessories for Enclosures Extensive range of universal accessories Accessories for 19" Racks Universal accessories for 19" equipment

Accessories for 19" Racks Universal accessories for 19" equipment

Modifications & Finishing All the customising services you need

Modifications & Finishing All the customising services you need Bespoke Enclosures Bespoke metal enclosures and sheet metal parts

Bespoke Enclosures Bespoke metal enclosures and sheet metal parts

News

News Press Releases

Press Releases Blog

Blog

Specifying Customised Enclosures

Specifying Customised Enclosures ROHS / WEEE Directives

ROHS / WEEE Directives Discontinued Products

Discontinued Products Temporary-Updates

Temporary-Updates Privacy Policy - GDPR (EU) 2016/679

Privacy Policy - GDPR (EU) 2016/679 Cookie Policy

Cookie Policy

General Enquiries Form

General Enquiries Form How To Find Us

How To Find Us Worldwide Sales Network

Worldwide Sales Network